Aluminum Metal: Properties, Uses, and Its Benefits

Table of Contents

Introduction

Aluminium is a silvery white metal with its atomic number 13 represented by “Al”. Aluminium is a vital material in many industries because it is a lightweight, durable, and corrosion-resistant metal.

Aluminium is crucial in modern technology and infrastructure, from common household items to aerospace industry tools.

We will discuss in detail the complete properties of aluminium, its use in daily life, and the benefits we get from aluminium across various fields.

Properties of Aluminium

Different types of physical and chemical properties make aluminium a valuable metal for various industries. A comprehensive detail of all properties of aluminium:

1. Corrosion Resistance

Aluminium forms a protective oxide layer, which makes it a highly corrosion-resistant metal. Thin and strong layers of aluminium oxide differentiate aluminium as a strong metal from other metals, unlike iron, which rusts and degrades over time when exposed to air. However, when Aluminium is exposed to oxygen, it forms a protective layer around 2–5 nm thick. Its thickness can be artificially increased by anodising and enhancing corrosion resistance.

The best corrosion resistance and its thickness make it ideal for outdoor applications.

Factor Effect on corrosion

Surface Treatment: Anodising, powder coating, and painting enhance protection.

Environmental exposure: Moist, salty, or acidic environments accelerate corrosion.

Temperature: High temperature can degrade protective coatings

Mechanical stress: Stressed areas corrode faster

2. Excellent Conductivity

Aluminium is an excellent conductor of heat and electricity, which is why it’s widely used in electrical wiring, heat exchangers, and cookware. But copper is considered a better conductor than aluminium. The thermal conductivity of aluminium is also utilised in heat sinks, which dissipate heat from electric devices.

3. Ductility and Malleability

The super-flexible properties of aluminium make it a favourite metal in various industries, such as automotive, aerospace, and packaging, where strong yet intricate designs really matter.

- Ductility refers to a material’s ability to be stretched into a wire without breaking.

- Malleability: This makes it ideal for producing thin foils, sheets, and various products that require molding or rolling.

- Aluminium is highly ductile, allowing it to be drawn into thin sheets and wires easily without breaking.

- It is also extremely malleable, allowing it to be rolled into foil or thin sheets.

- Its malleability makes it ideal for making cans, foils, and packaging materials.

4. Recyclability

Aluminium is one of the most sustainable and eco-friendly metals used today; therefore, recycling plays a crucial role in reducing industrial waste. Aluminium is a 100% recyclable metal; it can be melted and reused without losing its quality. The energy usage in aluminium recycling is notable. According to the Environmental Protection Agency, recycling aluminum saves about 5% of the energy needed to extract new metal ore from the Earth’s crust. A large amount of energy can be saved by recycling.

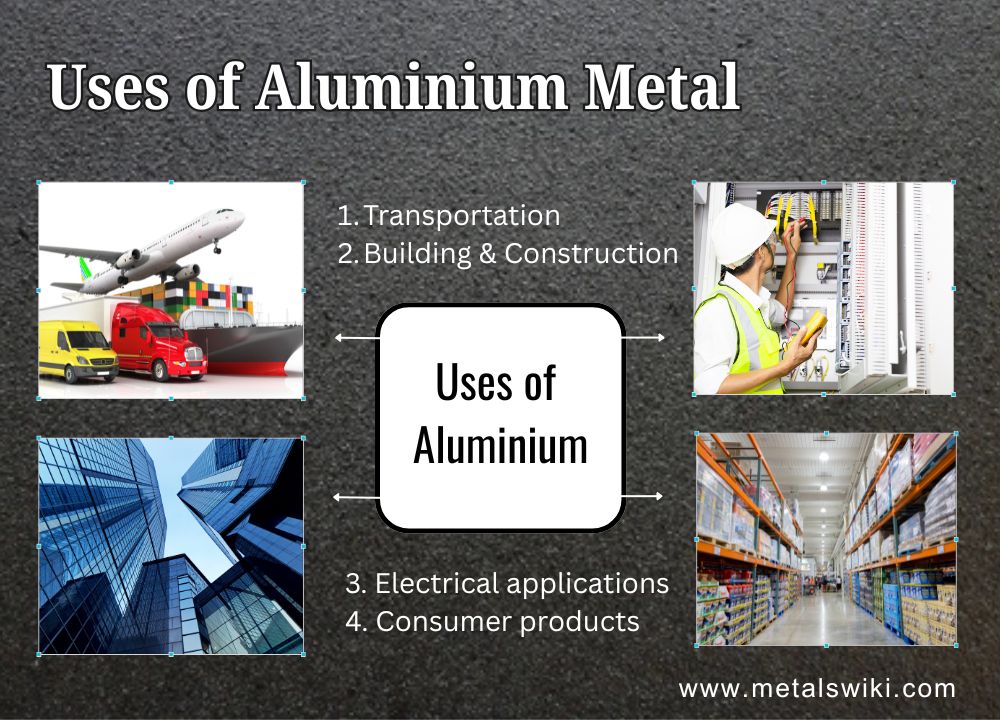

Uses of Aluminium Metal

Now, aluminium is used in almost every field of life, from household products to industries. The use of aluminium in large enterprises is explained in detail here.

- Transportation

- Building and Construction

- Electrical applications

- Consumer products

- Aerospace industry

Transportation

Aluminium plays a key role in transportation. Due to its lightweight strength and resistance to corrosion, the vehicle requires less force to move, resulting in improved fuel efficiency.

- Modern cars use aluminium for hoods and doors

- Alloys of Aluminium are crucial for reducing the weight of aeroplanes. Key parts, such as bulkheads, the tail section, overhead bins, and seats, are made of it.

- Aluminium is widely used in the frames of modern buildings

- Bicycle frames and wheels are commonly made of aluminium

Construction

Aluminium is used in construction for various purposes.

- Aluminium is used in modern building structures, such as glass facades, doors, and windows, because it is sturdy.

- Aluminium roofing and cladding provide lightweight, long-lasting protection for commercial and industrial buildings.

- Sometimes aluminium is used in bridge construction and large infrastructure projects due to its strength-to-weight ratio and corrosion resistance.

Electrical

Although copper is more conductive, aluminium is a more cost-effective and lightweight metal. The lightweight property of aluminium makes it the best choice for electrical wiring, particularly in

- Power transmission lines

- Electrical cables

- Busbars

- Electrical conductors.

Aluminium’s lightweight property also reduces the weight of electrical components.

Consumer Goods

Aluminium is an essential part of many household products.

- Aluminium is widely used in packaging, cans, and beverages due to its lightness and durability.

- Many household goods, such as refrigerators, air conditioners, and microwave ovens, contain aluminium for its corrosion resistance properties

- In the kitchen, various products like pots, pans, and baking trays are made up of aluminium.

Aerospace Industry

In the aerospace industry, aluminium is a game-changer. As mentioned above in the properties of aluminium, it possesses lightweight and highly resistant properties, which make it a suitable item in the aerospace industry. Aluminium is highly recommended due to its lightweight nature. Aluminium is used in space exploration technology, from satellite components to spacecraft hulls.

Advantages and Disadvantages of Aluminium

Here are some advantages and disadvantages of aluminium explained in a simple way:

Advantages of Aluminium:

Aluminium, as compared to other metals like steel and iron, offers important properties and advantages. Here is a complete detail of the Advantages of Aluminum

- Aluminium is the lightest metal, providing benefits to industries where weight reduction is crucial, such as automotive, aerospace, and construction.

- The best feature of aluminium is its natural resistance to rust. Aluminium retains its strength and flexibility even at sub-zero temperatures.

- It is an excellent conductor of heat and electricity. Aluminium is non-magnetic and non-sparking, making it safe and useful in inflammable environments, such as electronic devices and MRI machines.

- Aluminium is 100% recyclable without losing its original properties. It acts as environment friendly.

- Aluminium has a modern, attractive appearance and is widely used in architecture, furniture, and consumer products.

Disadvantages of Aluminium

As aluminium has various advantages, it also has some disadvantages, which make it less used in some industries.

- Although aluminium is strong for its weight, it does not have the tensile strength of steel.

- Aluminium is an expensive metal compared to steel and some other metals, making it a less economical option for certain projects.

- On heating, it expands more than steel

- Aluminium has low resistance to abrasion and friction as compared to harder metals.

These are the three best properties of aluminium,

- Aluminium is a lightweight metal

- It is the best corrosion-resistant metal

- Aluminium is highly malleable and ductile

Aluminium is widely used in large industries, such as aerospace (aircraft, satellites), transportation (cars, trains, ships), packaging (aluminium foil, beverage cans), construction (windows, doors), and electrical (wires, conductors).

Yes, aluminium is 100% recyclable without any loss in quality. Recycling aluminium requires significantly less energy (around 5% of the energy used for producing new aluminium) and reduces environmental impact, making it a highly sustainable material.

Yes! It is a good conductor of heat and electricity. It is commonly used in electrical wiring, power lines, and cables due to its ability to carry electrical current efficiently, while also being lighter and more cost-effective than copper.

The mixture of Aluminum with other metals, such as copper, magnesium, or silicon, is called an aluminum alloy. In its pure form, aluminium's strength is not as great as when mixed with other metals, so its alloys are created for better use. The aluminium alloys are designed to improve certain properties, such as strength, hardness, and resistance to wear. They are used in various applications, from aerospace to automotive, to enhance the performance of the base metal.

Newsletter

Latest Post